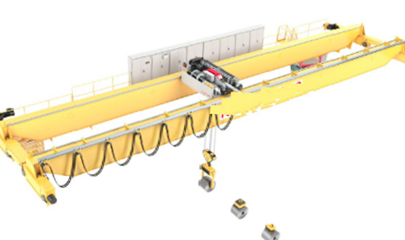

Crane Automation

We provide every type of overhead crane automations, from basic standard models to unique tailored cranes designed for the most demanding lifting requirements. Our automated cranes make your life easier. Imagine your processes more streamlined and the safety in your facility greatly enhanced. This is what you get with our automated cranes.

We make two types of automated cranes. In the semi-automatic, various features assist the operator, but allow more manual control. With a fully-automated crane, the operator makes the settings, and the crane automatically takes care of repetitive or difficult actions. This is especially useful in demanding and hazardous environments. Automated cranes can reduce labor costs, track inventory, optimize storage, reduce damage, increase productivity and reduce the capital expense associated with forklift systems.

Electromagnetic Crane is a kind of lifting machine that uses electromagnetic principles to carry steel articles.The main part of the electromagnetic crane is the magnet. Switch on the current, the electromagnet steel items to absorb, transport to the designated place. Cut off the current, the magnetism disappears, and the steel stuff comes down. Electromagnetic crane is very convenient to use, but it must be used with the current. It can be used in waste steel recovery department and steelmaking workshop.

Laser scanners detect the edges and ends of the container,The controls position the trolley, chassis, and spreader, Cameras read the container IDs and communicate with the yard director computer.

The load precisely follows the operator input, even with the higher loads currently being used.

The yard achieves a higher rate of productivity than previously possible, often setting production records.

All the drives are on the LAN, so all motors have the same nstantaneous response to operator inputs.

System scalability allows a smooth integration of advanced options.

Laser scanners detect the edges and ends of the container.

The controls position the trolley, chassis, and spreader.

Cameras read the container IDs and communicate with the yard director computer.

In the semi-automatic, various features assist the operator, but allow more manual control. With a fully-automated crane, the operator makes the settings, and the crane automatically takes care of repetitive or difficult actions. This is especially useful in demanding and hazardous environments.

Automated overhead cranes can reduce labour costs, track inventory, optimise storage, reduce damage, increase productivity and reduce the capital expense associated with forklift systems. Some common applications include steel coil and paper roll handling, waste-to-energy, shipbuilding, container handling, food production, metals processing and general manufacturing. Every crane from utilises the most recent developments in software and engineering to ensure it is the most advanced it can be on delivery. As technology develops, our cranes are designed to make modernisation easy.

CRANE CONTROL SYSTEMS:

The crane management system is the centrepiece for precise and reliable crane operation. Litronic from Liebherr is a unique one-system-solution which unites the best technologies available for reliable crane control.

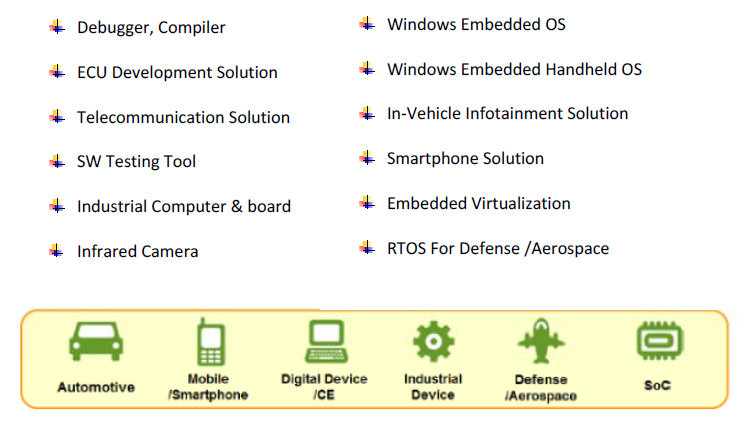

BUSINESS VERTICALS